Hybrid multi-mode water recovery processor

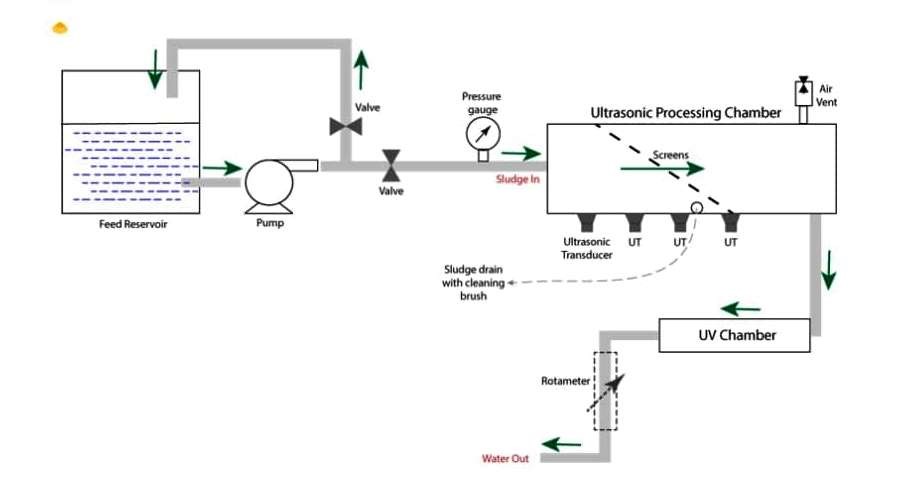

Objective: Equipment for water recovery that incorporates ultrasonic agitation, multilevel filtration, and ultraviolet disinfection for a variety of water such as surface water, wastewater and sludge feeds, with minimum downtime and acceptable quality of treated water water.

Design Basis & Limitations:

- Designed for handling tertiary treated water as well as surface water. The operating temperature is within the range of 30 to 50 Deg. C

- Feed flow rate range 5 lit to 30 lit. /min.

- The outlet from UV system is open to atmosphere.

2. Dimensions:

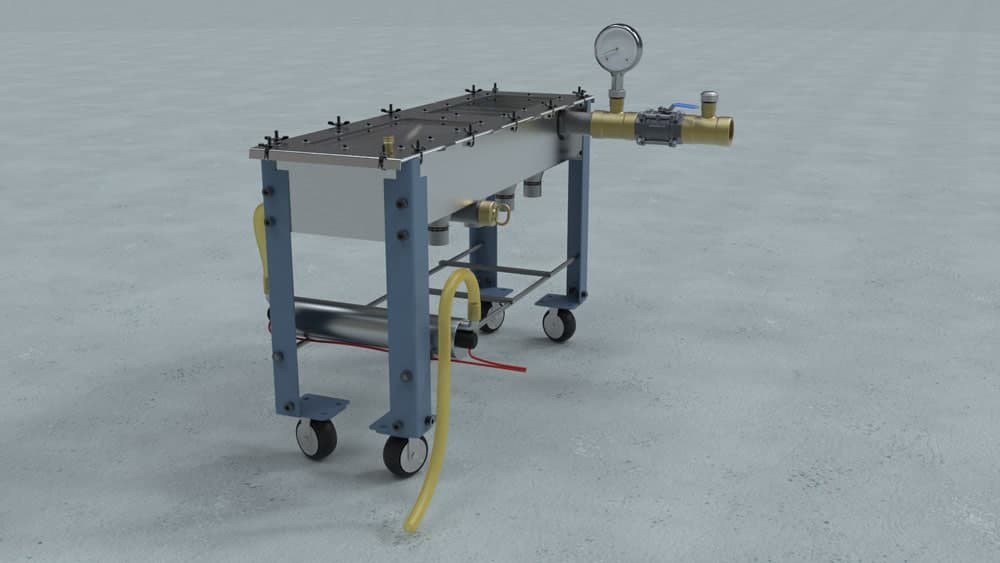

Ultrasonic processing vessel dimensions 0.65 x 0.15 x 0.1 meters, 9.75 litre volume, approximately 9 litres active capacity. Ultrasonic vessel is above 30 cm from ground, UV chamber) is 12 cm below it. Vessel heights are adjustable to some extent.

Entire assembly is trolley mounted for convenience.

3. Piping and fittings:

- As far as possible, the piping is flexible PVC.

4. Ultrasound Chamber:

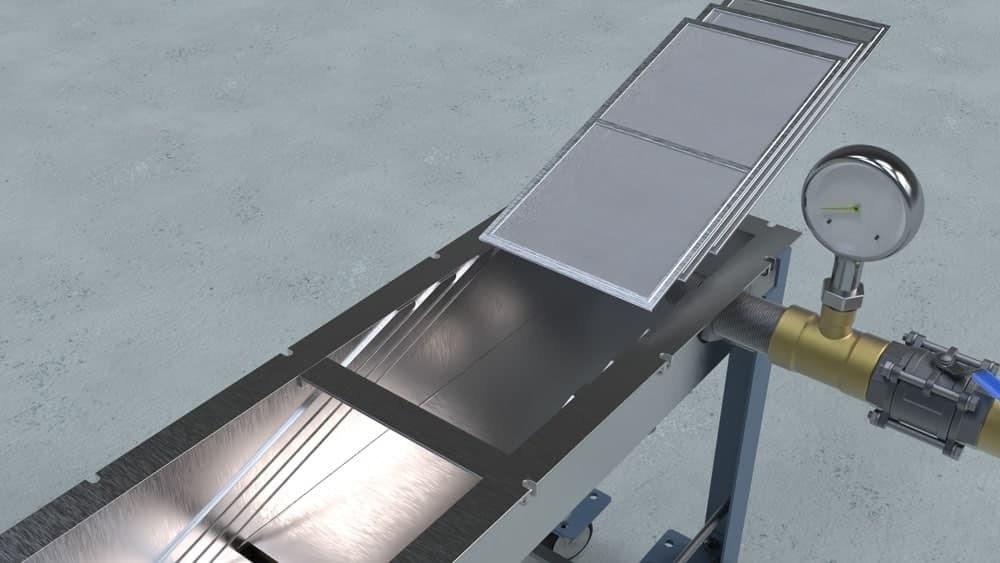

SS vessel with the top cover fitted with swing nuts. The chamber is divided into two sections by three sets of removable screens fitted diagonally. Array of ultrasonic transducers at bottom plate of the vessel serve dual purposes: Disintegration of particulate clumps and biomatter, as well as vibration of the filter screens to enhance their efficacy and mean-time-between-servicing.

A sediment trap is provided at the bottom of the ultrasound section with provision for intermittent cleaning without disturbing the operation.

5. UV section:

To cover wide range of throughput, we have specially designed the UV section in lieu of sourcing standard UV systems from the market. the special features of our design are to fix several baffles to force the water through the UV chamber in circular motion rather than in axial direction as usual UV systems. The chamber is double walled (SS jacket, quartz sleeve), with this enhancement of baffles designed to prevent Coriolis effect in fluid flow. This also avoids the requirement of high flow rate: The baffles provide sufficient turbulence to avoid film formation even at low flow rates.

No pump is provided between the output line of the filtered water to the input into the UV section. The filtered water will flow by gravity. A rotameter is provided at the outlet of the UV chamber.

The following computer-generated pictures show the simple flow sheet and different sections of the prototype:

Simplified flow sheet of the Hybrid Unit

A computer-generated model of the prototype

Placement of screens in the Ultrasound chamber

Positioning of the ultrasound transducers in the chamber

Managing Innovation can design and delivering similar combo units for different sizes as well as for purifying Surface water to potable quality water with minor modification. Currently the system is functional at IIT Kharagpur for sludge treatment.