Specification of Batch / Continuous Sonicator

SPECIFICATIONS:

A picture of the base smallest unit (120 Watt) in batch operation is shown below:

| TEMPERATURE CONTROL | : Digital temp. indicator controller with sensor is provided to switch off machine in case temp of processing liquid rises above set point |

| Timer | : 0-30 minutes digital timer is provided to set processing time |

| Timer | : Cyclic timer is provided with ON and OFF pulsating time settings |

| Power Meter | : Watt meter is provided, connected to mains for monitoring actual power consumed by the equipment |

| Recommended Vessel | : For batch operation, we recommend a vessel diameter of 6 cm, and sonicator tip should be submerged in the liquid with least 8 cm both above and below the tip. |

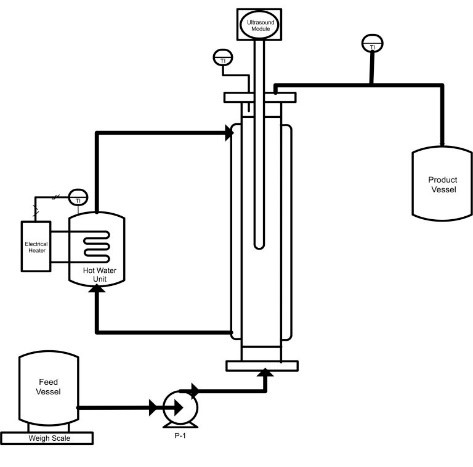

For continuous flow operation, we can provide the complete fabricated unit with our specially designed tubular reactor section for higher efficiency

For a residence time of 10 seconds in this cavitation zone (which is very common for most of the applications), this reactor will be able to process more than 2 KL of liquid /Day.

A flow sheet for complete continuous flow lab unit is shown below: